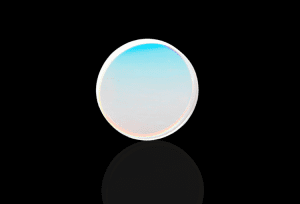

Sapphire Windows

Sapphire Windows for Stringent Applications

When it comes to demanding conditions and harsh environments, sapphire windows stand as the ideal choice. Sapphire, renowned as the second-hardest material on Earth after diamond, boasts remarkable resistance to various chemical acids and alkalis. Moreover, it exhibits outstanding scratch resistance, a high dielectric constant, and exceptional thermal conductivity.

At Avantier, we employ single-crystal sapphire to craft high-quality sapphire windows and precision optical components. Leveraging sapphire’s robust mechanical strength, we can produce optical windows that are thinner and offer superior transmittance compared to other dielectric windows. Uncoated sapphire excels in transmitting light within the 170 nm to 5.5 µm range. We specialize in custom windows tailored to your specific requirements, and our dedicated design team is eager to collaborate on finding the optimal optical solution for your needs.

Sapphire Windows in High-Temperature Environments

Sapphire’s remarkable heat tolerance, with a maximum temperature rating nearing 2000 °C, positions it as the go-to choice for applications such as lamp shields, high-temperature combustion chambers, furnace systems, and gas processing. Supported sapphire windows maintain peak performance up to 1700 °C and can even endure temperatures reaching 1950 °C without any alteration in shape and only a marginal decrease in optical performance.

This thermal resilience sets sapphire apart from other optical materials. By contrast, fused silica, the closest alternative, begins to deteriorate at 1000 °C and melts entirely at 1650 °C.

Additional Advantages of Sapphire Windows

Sapphire’s inertness in the presence of molten metals, acids, and caustic agents (except for hot caustic salts) renders it an ideal choice for plasma chambers, sapphire lamps, and scenarios where heat and corrosive substances would wreak havoc on any other optical substrate. Its chemical inertness is also prized in medical and pharmaceutical applications, ensuring the purity of surrounding substances.

The structural robustness of sapphire opens doors to various applications where high pressures would compromise other optics, including aircraft sensors, deep-sea windows, and sight windows on pressurized experiment vessels.

Sapphire’s exceptional resistance to scratches guarantees consistent optical clarity even in abrasive conditions or exposure to sand and grit that would mar other optical materials. This quality positions sapphire as a prime choice for optical windows in smartphone cameras, gun sights, and downhole and drilling vision systems.

Sapphire demonstrates excellent transmittance in both UV and IR ranges, with thinner windows enabling deeper UV and IR transmission. Our ultra-thin sapphire windows are designed for profound transmittance.

Key Specifications for Avantier Sapphire Windows

Our factory standard entails a clear aperture covering at least 90 percent of the diameter, with a surface quality rating of 80-50 scratch dig. Birefringence for visible light in directions to the optic axis is 0.008, and the crystal axis cut is random. We can accommodate c-cut and tighter surface quality specifications upon request.

Material |

Optical Sapphire (Al2O3) |

Dimension |

+0, -0.2mm |

Surface Flatness |

1λ per 25 mm at 633 nm over clear aperture |

Surface Quality |

80-50 scratch and dig, beveled edge |

Crystal axis cut |

random (c-cut available upon request) |

Birefringence (nE-nO) |

0.008 for visible light in directions

|

Refractive index |

1.77 @500nm |

Center Thickness (CT) |

+/-0.1 |

Parallelism |

3 arc minutes |

Clear Aperture |

90% |

Coating |

none |

Diameter(mm) |

Thickness(mm) |

Diameter(mm) |

Thickness(mm) |

2.5 |

0.5 |

23.75 |

1.0 |

5.0 |

1.0 |

25.0 |

2.0 |

6.35 |

0.5 |

25.0 |

2.3 |

7.5 |

0.4 |

25.4 |

1.0 |

9.5 |

0.5 |

25.4 |

2.0 |

10.0 |

1.0 |

25.4 |

2.25 |

12.7 |

1.0 |

30.0 |

1.0 |

12.75 |

1.0 |

31.75 |

1.0 |

13.0 |

0.5 |

35.0 |

1.0 |

15.0 |

2.0 |

38.1 |

1.0 |

17.25 |

2.0 |

38.1 |

2.0 |

20.0 |

1.0 |

40.0 |

1.0 |

20.0 |

2.0 |

50.8 |

2.0 |

22.0 |

1.0 |

50.8 |

3.15 |

For further details on our manufacturing tolerances or to request custom sizes and specifications, please contact us if you’d like to schedule a consultation or request for a quote on your next project. If you are looking for stock options, visit Stock – Sapphire Windows.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.