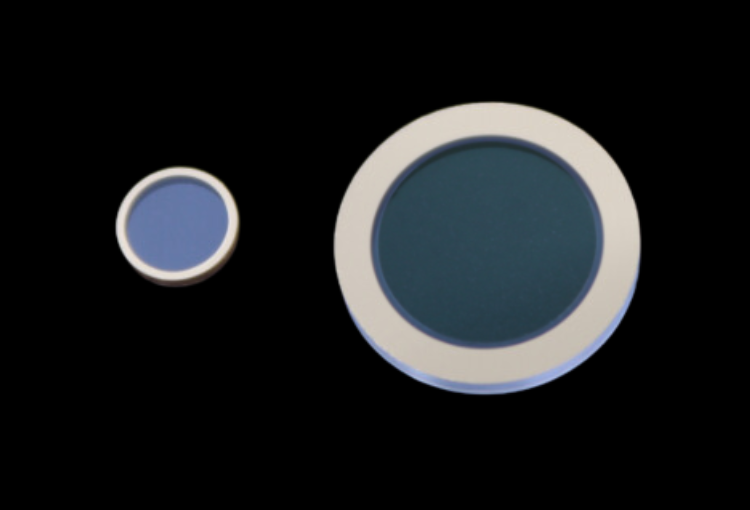

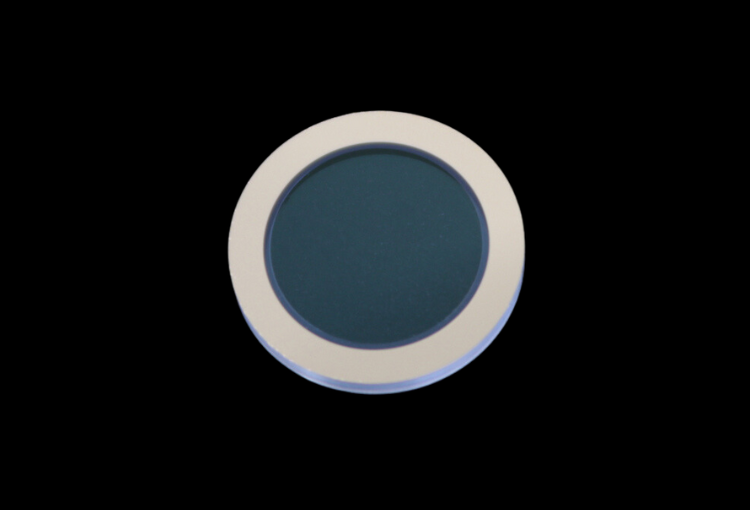

Metallized Sapphire Windows

Metallized Sapphire Windows incorporate metallized edge surfaces, enhancing their versatility for numerous applications and providing distinct key features. These windows can be soldered or bonded directly into opto-electronic assemblies, resulting in a hermetic seal, making them a valuable choice for various demanding environments.

Key Features

- Solderability: Metallized Sapphire Windows are designed with thin layers of gold compounds applied around their edges, ensuring compliance with MIL-STD-883 solderability standards. This feature ensures reliable and secure integration into electronic assemblies.

- Hermetic Sealing: The metalized edge surfaces enable these windows to form a hermetic seal when bonded, effectively protecting sensitive components from environmental factors such as moisture, gases, and contaminants.

- Durability: Sapphire windows are renowned for their exceptional hardness and scratch resistance. This durability makes Metallized Sapphire Windows suitable for applications where robust protection is essential.

- Chemical and Plasma Sanitation: Metallized Sapphire Windows excel in environments where chemical and plasma sanitation processes are prevalent. Their robust construction can withstand harsh chemical reactions and extreme temperatures, making them ideal for use in industrial settings.

Applications

- Chemical Processing: Metallized Sapphire Windows find extensive use in chemical processing equipment where resistance to corrosive substances and high temperatures is critical. They ensure optical clarity and structural integrity under these demanding conditions.

- Plasma Applications: In plasma research and industrial plasma applications, these windows act as viewports, allowing observation and control of plasma reactions. Their resistance to plasma-induced damage is a key advantage.

- Infrared Imaging: Metallized Sapphire Windows are valuable components in infrared imaging systems. Their high transmission in the infrared spectrum, combined with durability, ensures clear and reliable imaging in thermal imaging devices and IR cameras.

- Medical Devices: Sapphire windows are employed in medical devices such as endoscopes and optical sensors. The metallized versions ensure airtight seals, preventing contamination of sensitive medical equipment and optics.

- Aerospace and Defense: In military and aerospace applications, Metallized Sapphire Windows are used in optical systems and sensor assemblies, where their robustness and resistance to harsh conditions are vital for reliable performance.

- Scientific Instruments: They are used in various scientific instruments, including spectrometers and laser systems, where optical precision and long-term performance are required.

- Opto-Electronic Assemblies: These windows are a crucial component in opto-electronic assemblies across industries, ensuring optical integrity and protection of delicate electronic components.

Metallized Sapphire Windows are versatile and durable optical components with key features like solderability and hermetic sealing. Their ability to withstand harsh environments and their applicability in diverse fields, from chemical processing to medical devices and aerospace, makes them an indispensable choice for optical and opto-electronic applications requiring exceptional performance and reliability.

Factory Standard

Substrate Material: | Sapphire |

Dimension: | Ф2.5mm x 0.28 mm, Ф2.9mm x 0.28mm or customer requirement |

Center Spectrum: | 1270 ~ 1650nm or customer requirement |

Metallization: | CrNiAu/TiNiAu/TiPtAu or customer requirement, Au80Sn20 Solder Coating |

Surface Quality: | 20/10 (MIL-PRF-13830B) |

Contact us today to discuss your optical needs and find the perfect windows for your requirements.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.