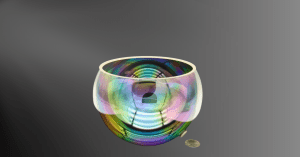

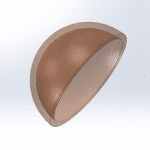

Custom Optical Domes & Precision Solutions

At Avantier, we specialize in custom optical dome solutions tailored to meet unique application requirements. Whether for aerospace, underwater imaging, or surveillance systems, we offer high-precision optical domes in a wide range of materials, sizes, and coatings.

Why Choose Avantier for Optical Domes?

- Tailored Design: No off-the-shelf products—each dome is custom-designed based on your specifications and performance goals.

- Collaborative Engineering: We work closely with clients to determine the optimal substrate, coating, and geometry for every project.

- Diverse Material Options: Choose from advanced optical materials, including fused silica, sapphire, magnesium fluoride (MgF₂), and zinc selenide (ZnSe).

- High-Precision Engineering: Our experts specialize in geometric precision, coating application, and optical clarity.

- Custom Mount Integration: We design and manufacture adapter interfaces and mechanical mounting features as needed.

- In-House Fabrication: Our modern manufacturing facilities ensure tight tolerances, repeatability, and cost-effective production.

- Performance with Value: We deliver high-quality optical domes at competitive prices—optimized for both performance and budget.

Manufacturing Capability

| Material | BK7, CaF2, Cleartran, Fused Silica, MgF2, Germanium etc |

| Diameter | 2~500mm |

| Thickness | >1mm |

| Coating | AR coating for VIS, SWIR, NIR, MWIR, LWIR, broadband |

| Surface Accuracy | 1/10-1 lambda |

| Dimensional Tolerance | +/-0.1mm |

| Surface Quality | 20/10-60/40 |

| Clear Aperture | 90% |

| Environment Testing | Extreme cold-heat cycle, sand blasting, salt water, adhesive test |

| Specification Testing | Qualification Test, Optimization Test, Dimensional Test, According to DIN, ISO and MIL standards |

Stock Optical Domes

Germanium Optical Domes

| Part Number | Size (mm) | Tolerance (mm) | SD | Coatings | Prices (USD - 5 pcs) | Price (USD - 10 pcs) | Delivery Time |

|---|---|---|---|---|---|---|---|

| AVTGD-1001 | D 25.4 x 3 | +/-0.1 | 60-40 | Tavg≥97%@8-12um | $570.00 | $540.00 | One Week |

| AVTGD-1002 | D 50.8 x 3 | +/-0.1 | 60-40 | Tavg≥97%@8-12um | $1,110.00 | $1,015.00 | One Week |

| AVTGD-1003 | D 76.2 x 3 | +/-0.1 | 60-40 | Tavg≥97%@8-12um | $2,125.00 | $2,000.00 | One Week |

| AVTGD-1004 | D 101.6 x 3 | +/-0.1 | 60-40 | Tavg≥97%@8-12um | $3,850.00 | $3,690.00 | One Week |

The minimum order quantity is 5. Also available in volume pricing, please contact Avantier for details.

Please note that prices are subject to fluctuation and may change without prior notice. For the most accurate and up-to-date pricing information, kindly contact our office. Additional shipping fees will be calculated and added to your total order.

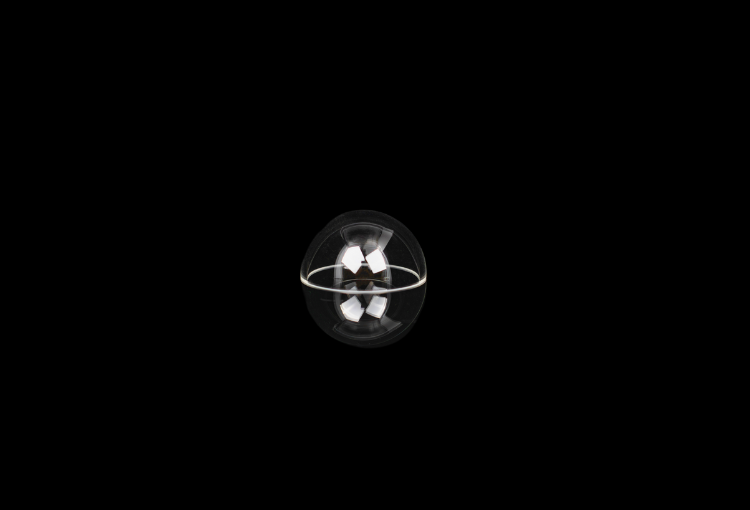

Sapphire Optical Domes

| Part Number | Size (mm) | Tolerance (mm) | SD | PV | Prices (USD - 5 pcs) | Price (USD - 10 pcs) | Delivery Time |

|---|---|---|---|---|---|---|---|

| AVTLB-0010 | D 25.4 x 3 | +/-0.1 | 60-40 | 1/2λ | $425.00 | $395.00 | One Week |

| AVTLB-0012 | D 50.8 x 5 | +/-0.1 | 60-40 | 1λ | $750.00 | $650.00 | One Week |

| AVTLB-0013 | D 76.2 x 5 | +/-0.1 | 60-40 | 1λ | $1,000.00 | $850.00 | One Week |

| AVTLB-0014 | D 101.6 x 5 | +/-0.1 | 60-40 | 1λ | $1,150.00 | $1,000.00 | One Week |

How to Select the Best Optical Domes

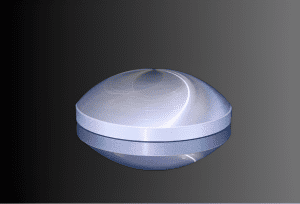

Fused Silica Dome

- Transmission Range: 300 nm–2 µm

- Ideal for: Visible and UV imaging

- Features: High chemical and pressure resistance

- UV Option: Over 85% transmission down to 185 nm with UV-grade fused silica

Sapphire Dome

- Transmission Range: 2–5 µm (infrared)

- Ideal for: Harsh environments (defense, deep-sea imaging)

- Features: Exceptional scratch resistance and abrasion resistance

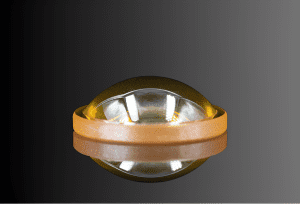

Germanium Dome

- Transmission Range: 2–14 µm (IR)

- Best for: IR imaging in rugged conditions

- Features: Can be coated with diamond-like carbon (DLC) for enhanced durability

Zinc Selenide (ZnSe) Dome

- Transmission Range: 3–16 µm

- Ideal for: Controlled IR imaging environments

- Notes: Requires AR coating due to high refractive index; lower durability than sapphire

Magnesium Fluoride (MgF₂) Ceramic Dome

- Transmission Range: 2–7.5 µm

- Strength: 1350 kg/mm² Knoop hardness

- Benefits: High flexural strength, custom shapes via hot pressing

- Applications: Launch tubes, missile systems

Technical Resource

Design Considerations for Optical Domes

Effective dome design is essential for reducing optical distortion and preserving image quality. Key design factors include:

- Material Selection: Ensure both optical and mechanical performance (refractive index, dispersion, strength).

- Curvature: Influences field of view (FOV), distortion, and clarity. Must align with application requirements.

- Optical Coatings: Anti-reflective coatings improve transmission and reduce glare.

- Environmental Resistance: Domes must handle pressure, temperature extremes, and abrasion, especially in aerospace or underwater use.

- Mounting & Sealing: Secure sealing prevents contamination and maintains system integrity.

Advantages of Optical Domes vs. Flat Windows

- Wider Field of View: Domes allow sensors to detect signals from multiple angles without distortion.

- Reduced Chromatic Aberration: Especially at wide angles, domes outperform flat windows in color accuracy.

- Lower Optical Aberration Underwater: Better refraction handling compared to thick flat windows.

- Superior Pressure Resistance: Domes naturally distribute pressure, allowing thinner construction with better optical performance.

Key Applications

- Wide-View Cameras & Sensors: Protects optics, reduces reflections, improves performance across angles.

- Underwater Imaging: Smooth refractive transitions between water and air maintain clarity.

- Aerospace & Defense: Essential for aircraft, drones, and missiles in targeting and reconnaissance.

- Scientific Instruments: Supports telescopes, spectrographs, and environmental monitoring.

- Security & Surveillance: Shields optics in outdoor and high-risk environments

Additional Benefits Based on Substrate Choice

At Avantier, we help you choose the best substrate for your needs:

- Glass Domes: Excellent durability, scratch and chemical resistance, thermal stability, and easy maintenance. Cost-effective for many applications.

- Acrylic Domes: Lightweight and impact-resistant. Lower scratch resistance than glass but more affordable and mechanically stable.

Optional Enhancements:

All dome types can be enhanced with anti-reflective or protective coatings for added performance.

Custom Optical Domes

At Avantier, we specialize in creating custom optical dome solutions tailored to meet our customer’s specific requirements. Instead of offering a static list of catalog options, we collaborate closely with our clients to understand their applications and recommend suitable substrates, coatings, and geometric designs for optimal performance.

Experience the reliability and high quality of Avantier’s custom optical domes solutions for your next optical system project.

FAQs

- How do I choose the best substrate material for my optical dome application? – Selection depends on your spectral range, environment, and mechanical requirements. For example:

- Fused Silica: Ideal for visible/UV with high chemical resistance

- Sapphire: Great for harsh environments with high abrasion resistance

- Germanium or ZnSe: Suitable for IR imaging

- MgF₂ ceramic: High-strength applications like missile systems

- What is the difference in optical performance between domes and flat windows? –

Optical domes offer:

- Wider field of view

- Less chromatic and spherical aberration at wide angles

- Better refraction handling underwater

- Higher pressure resistance with thinner construction

- What manufacturing tolerances and quality can I expect from Avantier optical domes? –

Avantier delivers:

- Diameters from 2–500 mm

- Dimensional tolerance of ±0.1 mm

- Surface accuracy up to 1/10λ

- Surface quality from 20/10 to 60/40

- AR coatings for VIS to LWIR ranges

- Clear aperture ≥ 90%

- Can I integrate optical domes with custom mounts or housings? –

Yes. Avantier provides custom mechanical mounting solutions and adapter interfaces designed to fit your system, ensuring environmental sealing and system compatibility.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.