Key Takeaways:

- This case study explores the optical system design optimization of fixed-focus lenses, emphasizing the simplicity and high technical precision of the double Gaussian structure.

- Key improvements involve increasing the edge thickness of certain lenses to prevent breakage during processing.

- By expanding lens diameters and addressing material issues, production risks were mitigated. Additionally, enhancements in microscopic objective design, such as adding lenses and optimizing aberration distribution, improved performance close to the diffraction limit.

- Avantier’s material selection and adjustments bolstered lens robustness and manufacturability, ensuring higher quality and consistency in final products.

Introduction to Optical System Design Optimization

A fixed-focus lens is a lens with only one fixed focal length. Compared to zoom lenses, fixed-focus lenses are simpler in design. Therefore more easily achieve demanding technical parameters, such as large entry pupil diameters.

The double Gaussian structure is a common fixed-focus lens structure, generally composed of 6 pieces, the front and the back one for the meniscus lens. Additionally, the stop is in the middle of the lens, and the entire structure is close to symmetry. This means that it is easy to correct aberrations related to the field of view such as coma, distortion, magnification and chromatic difference of magnification. While the double Gaussian structure has been known for nearly 200 years, it and its variants are still widely used today.

Lens Design

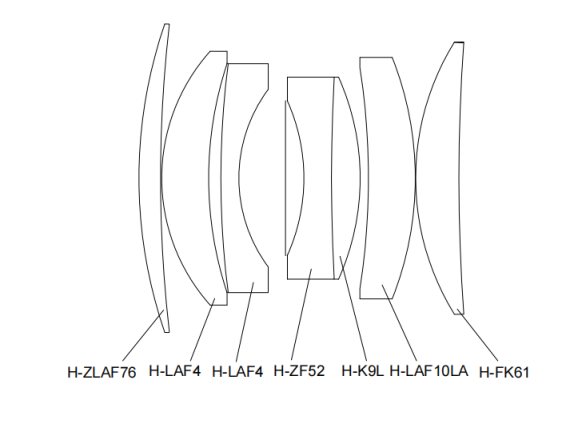

The drawing below by the customer shows the design of a double Gaussian variant structure. The design performs well, but the details need refinement. From an optical lens processing perspective, the first and fifth pieces of glass are positive lenses with thin edges, making them prone to breakage during processing. The diameter of the first lens is 78mm, and the edge thickness should ideally exceed 2.5mm. The diameter of the fifth lens is 48mm, and the edge thickness should preferably be greater than 2.2mm. However, in the current design, the edge thickness of these two lenses does not meet reasonable values, posing a production risk. During the mechanical design process, the outer diameter of the lens needs to be expanded. This makes processing these two lenses impossible.

Material Selection

In terms of materials, although the design uses conventional glass materials, the last piece is H-FK61. H-FK61 has a high Abbe number and is commonly used to correct chromatic aberration. However, this material is soft and difficult to process, resulting in a low pass rate. Additionally, this piece of glass is exposed to the environment, and even with the protection of an AR film layer, there is still a risk of scratches on the lens surface if it needs to be wiped. Therefore, Avantier may consider replacing H-FK61 in this case, as this piece of glass does not serve a chromatic correction function. Replace H-FK61 with H-QK3L, which has a similar refractive index, and control the minimum side thickness of the lens to optimize the design as follows, and the whole design will be more reasonable.

Optimization of the optical system of the microscopic objective

Tolerance analysis is typically executed after the initial completion of optical system design. Due to the deviation of optical components and assembly from the ideal state, the performance of the actual production is often different from the design performance. Thus, a good design should reduce the impact of tolerances to an acceptable level. In contrast, tolerance-sensitive design is meaningless for production and processing.

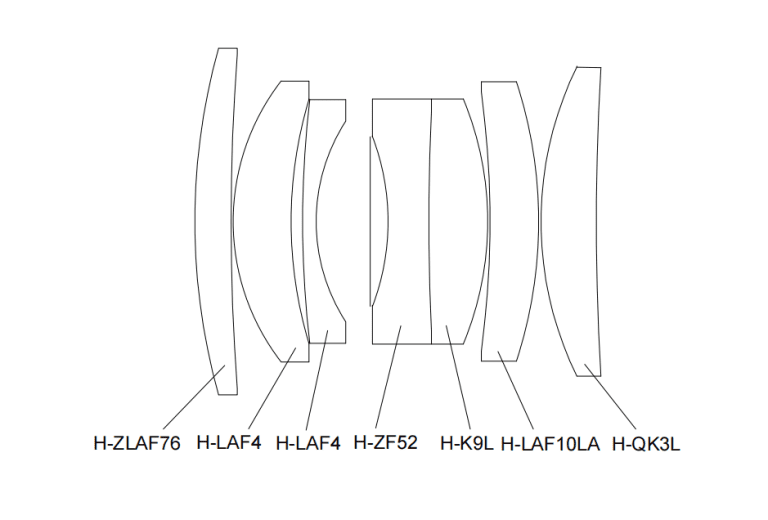

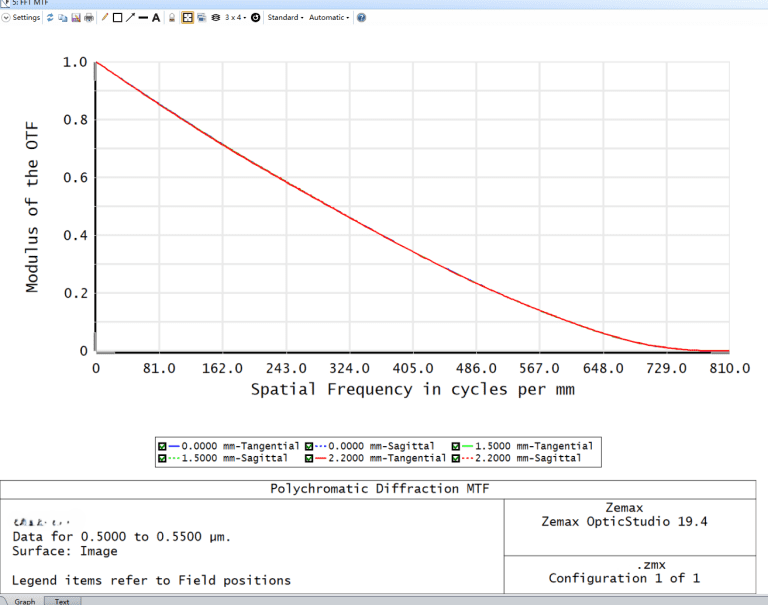

The following is a 5X long working distance micro objective lens, a total of 7 lenses, designed to achieve the diffraction limit.

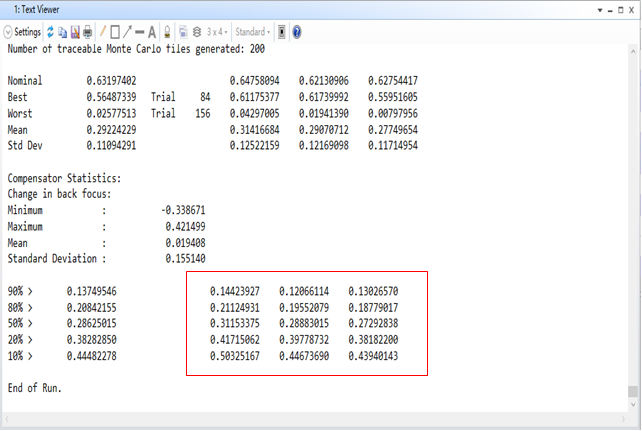

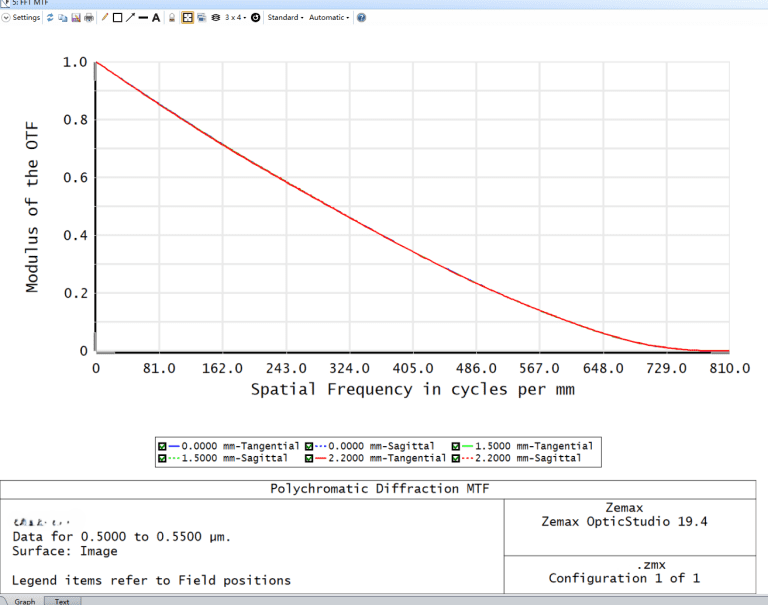

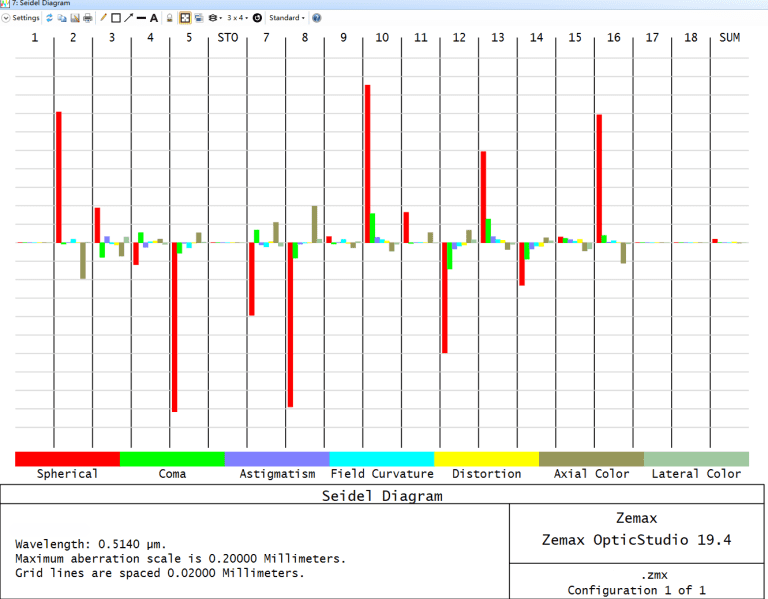

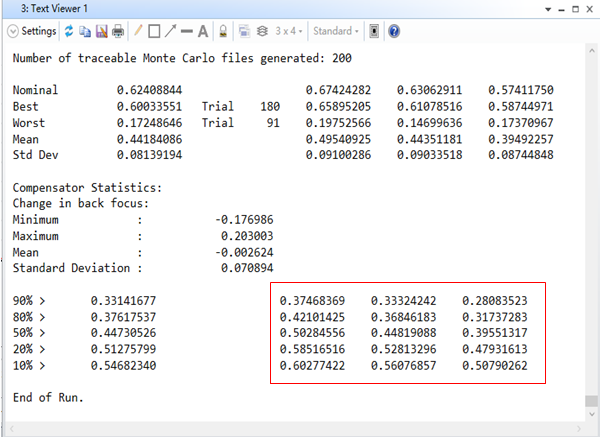

The problem with this design is that the distribution of aberrations is not uniform, and lenses bearing large aberrations are often sensitive components to tolerances. Furthermore, tolerance analysis is carried out on MTF@200lp/mm, and the results obtained are as follows. Subsequently, the simulated results show that the actual assembled products will have a large performance attenuation.

Compared to the previous design, the tolerance sensitivity of the new design is significantly reduced. Also, the performance attenuation is relatively small. According to the simulation results, the lens with good performance can be obtained by adjusting it in the later stage.

Conclusion

In conclusion, the optimization of optical system design for both fixed-focus lenses and microscopic objectives highlights the critical importance of meticulous material selection, structural adjustments, and tolerance analysis. By addressing specific issues such as inadequate edge thickness in the lens design and replacing materials prone to processing difficulties, Avantier has significantly improved the overall robustness. Additionally, these changes have enhanced the manufacturability of the lens system. Furthermore, refining the design of the microscopic objective by adding an additional lens and optimizing the distribution of aberrations has resulted in a more stable performance. This improved design brings the performance closer to the diffraction limit. These enhancements not only reduce production risks but also ensure higher quality and consistency in the final optical products.

Avantier designs high-tech solutions tailored to your specific needs across various fields, pushing boundaries to deliver exactly what your project demands. Contact us for a consultation or request for quote on your next project.

GREAT ARTICLE!

Share this article to gain insights from your connections!